Adler's Antique Autos, Inc.

Author of "Notes from the Corrosion Lab"

801 NY Route 43, Stephentown, NY 12168

(518) 733 - 5749 Email

|

Articles

|

by Bob Adler

What's the best oil for your truck? Should you use non-detergent oil?

What's the best oil for your truck? Should you use non-detergent oil?

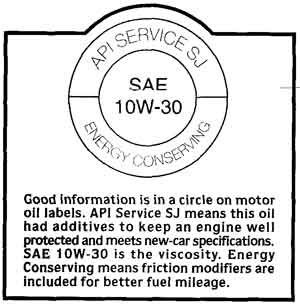

While I like original trucks, I prefer new oil. Modern lubricants should be used by people who want maximum life from their machinery. For gasoline engines, use oil with an American Petroleum Institute (API) rating of “SJ,” which is buried in fine print on the label. This oil meets new-car specifications and using it might be the single best thing you can do to preserve an engine. The “SJ” oil rating replaced “SH” in 1996.

Motor oil has come a long way from when our trucks were new. Additive packages cut down on wear and corrosion and extend drain cycles. Also, modern oils do not thin out as much when they are hot and pump easier when they are cold.

Additives

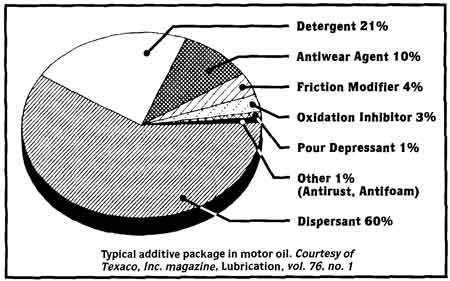

Before 1932, motor oil had no additives. The first benefit of research was pour-point depressants. These make oil pourable and pumpable in very cold engines. By the 1940s, detergents were developed to reduce valve sticking. These compounds are alkaline, so they also tend to neutralize acidic combustion by-products. This means there is less corrosion forming inside the crankcase, especially on the bearings and crankshaft. Early detergents were similar to laundry detergents. Other additives, dispersants, are similar to detergents, but work at low temperatures to solubilize sludge and prevent formation of its precursors.

Antioxidants and corrosion inhibitors were developed to protect alloy bearings. Antioxidants keep the oil from breaking down and extend its useful life. Interestingly, butylated hydroxy-toluene or BHT, the same stuff added to food packaging to preserve freshness, is added to oil. It is a free-radical trap. Corrosion inhibitors prevent rust by sticking to metal surfaces and preventing physical contact with water or corrosive material.

Developments in the 1950s brought multiviscosity oils. Polymer additives were found to retard oil thinning at high temperatures. With these additives an oil could meet both cold and hot viscosity specifications. The container is labeled for instance, 1OW-30 or 20W-40 where the first number (the W is for winter) is the cold specification and the second number is the hot specification. The 1955 Chevrolet Shop Manual was the first to recommend 1OW-20 or 1OW-30 for temperatures down to zero degrees Fahrenheit, and 5W-10 or 5W-2O below zero Fahrenheit. The advantages of multiviscosity oils are easier starting in cold weather, faster oil delivery to moving parts on start up, and adequate film strength under high-operating temperatures.

The late 1950s brought interstate highways, heavier trucks, and a decline in railroad utilization. As a result, antiwear and extreme-pressure additives were incorporated into motor oil in the 1960s. “Moly” or molybdenum disulfide is the most recognized friction modifier and extreme-pressure additive. With renewed interest in economy after the 1973 oil embargo, friction modifiers were introduced. These reduce internal engine friction, which results in better fuel economy of one to two percent.

The latest oil formulations concentrate on improving all of the above and reducing ash content to prolong the life of catalytic converters. That's what the labels refer to when they tout their product's energy conserving qualities.

The late 1950s brought interstate highways, heavier trucks, and a decline in railroad utilization. As a result, antiwear and extreme-pressure additives were incorporated into motor oil in the 1960s. “Moly” or molybdenum disulfide is the most recognized friction modifier and extreme-pressure additive. With renewed interest in economy after the 1973 oil embargo, friction modifiers were introduced. These reduce internal engine friction, which results in better fuel economy of one to two percent.

The latest oil formulations concentrate on improving all of the above and reducing ash content to prolong the life of catalytic converters. That's what the labels refer to when they tout their product's energy conserving qualities.

Additives in modern oil also help an old engine, whether it is in use or in storage. The classic objection to switching from non-detergent to detergent oil is the concern that detergent oil will break off large chunks of sludge and plug oil lines. However, detergent is good at keeping new deposits from forming but does little to remove old crusty deposits, except at the surface. Restoration authority Matt Joseph said, “There was an old, often-quoted urban legend that the switch would loosen deposits and send them into the oil stream. The theory was that the loosened deposits could plug oil passages. Research disproved this theory years ago. The effect of detergent engine oil on deposits is surface erosion only. There is no evidence that this switch has ever caused a plugging problem.”*

Texaco, Inc. advised that switching to a detergent oil was best done after an engine rebuild. They said: “Loose deposits can plug internal orifices, filters, etc. within the engine and worn rings, now freed up in cleaned grooves, can break and cause more engine damage." **

As the old truck hobby is gentrified, I believe, owners will overhaul questionable engines. At that point there's no question about using modern oil. Also note, some deposits may shake loose even with a steady diet of non-detergent oil.

After an oil change, any oil turns black fairly quickly from carbon. If non-detergent oil sits undisturbed for about a year, it turns clear because the carbon settles to the bottom. Modern oil will stay dark indefinitely because the carbon does not settle out.

I have seen oil pump screens plugged with sludge on engines torn down after fewer than 100,000 miles. The goo in the bottom of the pan can be so thick that it holds an impression of the oil screen, like a tire print in soft mud. I have also seen 200,000-mile engine oil pans extremely clean. Either I deposits never formed or they were all swept out at oil changes. I'll credit the latter scenario to using modern oil. The other additives also protect engines from wear, so it's not just detergent but a complete package that benefits the engine.

Viscosity

What viscosity is best? Your owner's manual may need updating if it is pre-1955. All manuals discuss viscosity for various temperature ranges. The 1937 Chevrolet owner's manual recommends low plus ten percent kerosene for temperatures below zero degrees Fahrenheit.

The 1953 owner's manual deletes kerosene and introduces 5W oil for temperatures lower than minus 10 degrees Fahrenheit. And in 1955, 5W-l0 or 5W-20 was used for these temperatures. Newer formulas will give a wider point spread on the cold/hot viscosity ratings. Many engine rebuilders recommend 5W-30 for breaking in an engine. New cars are usually filled with this grade at the factory also. Lower viscosity oils get to bearings faster on start up, which is the critical wear period. Kerosene detracts from an oil's lubricating qualities and should not be used, even if it was originally recommended by the manufacturer. Many owners tend to use heavier viscosity oil than necessary. Modern lighter oils can support heavier loads. The old argument that heavier oil will not burn as quickly in a worn engine has some merit, but heavier oil takes longer to pump up in a cold engine, which is a worse evil.

Synthetic oil

Should you use synthetic oil in your old truck? My opinion is no. Synthetic oil is best suited for very hot or cold operating conditions or if a vehicle will be accumulating many miles in a short time. Antiques rarely encounter these extremes. There is also the tendency to extend oil drain intervals with synthetic oil. An engine that gets little use should have an oil change annually, preferably in the fall before winter storage. This is well before the additive package is depleted in any oil, so the extra expense of synthetic oil is unnecessary. On an engine that sees few miles, crankcase moisture and gasoline dilution are the prime contaminants to remove at oil change.

For the ultimate in oil information, truckers have used oil analyzed by a commercial lab. This can tell all about internal engine conditions and warn about imminent failure.

Trucks stored outdoors, especially pre-1955 Chevrolets, are prone to water leaks down the hood center seam and into the engine through rocker cover air vents. To deflect the rain, throw an old rubber floor mat over the engine. Another crankcase water source is rain entering around the road draft tube. Permatex can cure this. For old machinery, whether it is used hard or in storage, I can think of no more cost effective preservation technique than using API rated “SJ” oil. Extended fuel mileage, decreased bearing wear, and easier starts are the benefits for trucks that get frequent use. The advantages for those in storage are less internal corrosion and a better film clinging to moving parts while the trucks are waiting for the next start up.

* Cars and Parts magazine; Matt Joseph's "Tool Bag" column; March, 2000; vol. 43, no. 3; p. 64.

** Personal communication Technical Information Center, Texaco, Inc. {Authors's note: This is the "politically correct" answer, avoiding liability if an engine is damaged.]

Bob Adler is owner of Adler's Antique

Autos, Stephentown, New York, and

specializes in GM truck restoration.

He can be reached at 518-733-5749.

Email