Adler's Antique Autos, Inc.

Author of "Notes from the Corrosion Lab"

801 NY Route 43, Stephentown, NY 12168

(518) 733 - 5749 Email

|

Articles

|

Drum Brakes

by Bob Adler

Over the years attitudes toward brake drum maintenance have changed considerably. Old parts and new philosophies need sorting out.

Over the years attitudes toward brake drum maintenance have changed considerably. Old parts and new philosophies need sorting out.

In the old days drums, especially truck drums, were hardly ever turned on a lathe. Drum scoring or gouging from lining rivet head contact was usually ignored. When new brake linings were put on a truck, the mechanic expected the linings to eventually wear into the irregular drum and achieve complete shoe contact. Now, every brake technician wants to turn drums down to remove all traces of imperfections. This creates a new problem by removing brake drum material. As the inside diameter of the drum increases, the drum thickness decreases. At some point the drum becomes too thin to work reliably and should be replaced. For drums up to 12” diameter, most brake shops will discard the drum if it is .060” over-size. Most new drums have the discard wear limit stamped on the edge. This can be problematic if a replacement drum is not readily available.

|

|

The solution is to avoid turning drums if not absolutely necessary. If a machinist warns that an old drum is past its discard size, all is not lost. Older drums were generally thicker castings than their modern counterparts, so they can be used past the corresponding discard size of a newer drum. For liability purposes, machinists reluctant to turn these drums.

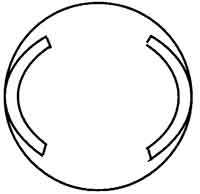

Turning drums creates, or exacerbates, another problem. If new shoes are installed on a drum that is grossly oversize, the smaller diameter shoe does not have a full initial contact patch on the drum. This gives poor stopping power until the shoe wears in and the friction material completely contacts the drum.

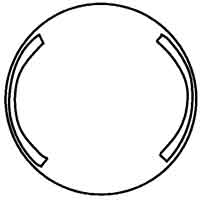

If there is uneven drum wear from side to side, the truck will pull to the side with more complete shoe contact, as that side has more friction. This problem will resolve itself after the shoes wear down enough to make full contact on the drum. In the old days a brake shop would “arc grind" new linings to completely seat on worn drums. That operation, however, is also lost to antiquity, especially due to the hazards of asbestos used in some linings. Lightly sandblasting the drum surface to roughen it may help seat shoes quickly.

|

|

|

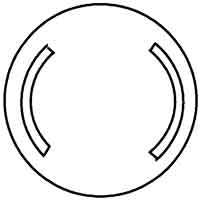

| Brake Drum worn oversize, new shoes retracted. | Oversize brake drum, apply new shoes- small contact patch, poor stopping ability. Mid section of lining must be lowered for full contact. | Drum brake linings seated, performance restored. |

There are some problems that do require drum turning or replacement. Deep cracks that can not be machined out are dangerous and require drum replacement. Do not confuse these with heat checking, (small hairline cracks that appear from temperature changes on the drum surface). These do not normally need to be machined out, as they are superficial and do not affect brake performance. Out-of-round drums cause a pulsating pedal, and should be machined to restore roundness. Drums with hard, raised, dark colored spots on the braking surface are “martensite spotted” which is caused by very high temperatures. Authorities recommend replacing these drums and correcting the cause of excessive heat. Grease stained drums, blue drums or polished drums do not need turning. Cleaning and hand sanding with 80 grit paper should suffice to return these to service.

|

|

|

|

Above Left: Cracked brake drum. Above Center: Martensite spotted brake drum. Above Right: Heat-checked brake drum. Lower Left: Greased-stained brake drum. Lower right: Scored brake drum. |

|

New drums are available for many older trucks at local parts stores. For example, Chevrolet half-ton drums are still in production for models back to 1951, and Chevy 3/4-ton drums, with some hunting, can be found back to 1954 models. But some one-ton drums from the 1970's are already obsolete and nearly impossible to find used in good condition.

My suggestion is to purchase new drums if old ones are seriously oversized, cracked, or martensitic, and new drums are readily available. Try machining if out of round or heavily scored. Tell the machinist to remove most but not all of the scoring. Don't let him ruin an irreplaceable drum by over cutting. If the drums are already oversize, consider reusing the old lining, if in good condition, since it is already mated to the drum. Before throwing anything out line up the replacement components. If you are purchasing used drums, check for oversize. Bring a new, lined shoe to see if the shoe seats properly or “rocks” from diameter mismatch.

Many ruined linings are due to leaky axle seals. New return springs will help prevent dragging brakes, and be less likely to break. Removing a drum with a broken return spring can be a real challenge. If custom linings are to be purchased, ask if extra thick friction material can be used, or if brass shim stock can be put between the shoe and lining to account for drum wear.

Bob Adler is owner of Adler's Antique

Autos, Stephentown, New York, and

specializes in GM truck restoration.

He can be reached at 518-733-5749.