Adler's Antique Autos, Inc.

Author of "Notes from the Corrosion Lab"

801 NY Route 43, Stephentown, NY 12168

(518) 733 - 5749 Email

|

Articles

|

Chevrolet Huck Brakes

by Bob Adler

There are a few tricks to a successful brake job that will last. This article will address Huck hydraulic brakes as used on Chevrolet and GMC half-ton trucks from 1936 to 1950, and to 1952 on some larger trucks, as well as many cars. Some points are useful for all brake systems. Consider this a 21st century supplemental to the original shop manual, which is still your ultimate weapon for restoration and maintenance.

There are a few tricks to a successful brake job that will last. This article will address Huck hydraulic brakes as used on Chevrolet and GMC half-ton trucks from 1936 to 1950, and to 1952 on some larger trucks, as well as many cars. Some points are useful for all brake systems. Consider this a 21st century supplemental to the original shop manual, which is still your ultimate weapon for restoration and maintenance.

Wheel Cylinders

First, crack the bleeder screw open. If it breaks off or won't budge even with heat, replace the complete wheel cylinder. Most of these cylinders are readily available new, and it is neither time nor cost efficient to use advanced life support to resuscitate originals. Most used cylinders have heavy pitting near the center which will not hone out. If a rubber piston cup rides on pits, it will have a shortened life span.

|

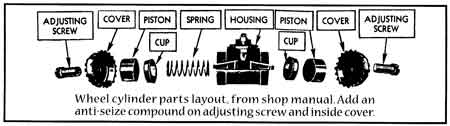

| Wheel cylinder parts layout, from shop manual. Add an anti-sieze compound on adjusting screw and inside cover. |

For cylinders that are not easily obtained new, sleeving is a viable option. Some companies use brass sleeves, other use stainless steel. Which is better? A stainless steel sleeving company claims its product is harder and more permanent than brass and won't undergo galvanic corrosion like brass can. A large brass sleeving company syas brass comes in more sizes, costs less, and that it gives a lifetime warranty. with virtually no corrosion claims. I asked my friend, Dr. Joe Strauss, who is a leading metallurgist, to arbitrate. He said there is no galvanic action without water inside the cylinder, which will destroy either type. Under normal conditions either brass or stainless steel would work fine.

Why not rebuild? One problem is aluminum pistons are factory anodized, but start corroding after years of service. Some of the kits currently available do not include these pistons. Also, some kits do not have the adjusting screws or end covers which notoriously corrode. The rubber cups in old NOS kits will be deteriorated and need replacing with recently manufactured cups.

If you will be using silicone brake fluid, specify EPDM rubber for the cups. Manufacturers are reluctant to confirm their products are silicone compatible. EIS was an exception, but they were recently bought out by Wagner, who would not recommend silicone with its products.

Original Huck wheel cylinders had annular rings machined around the inlet port, which helped seal the copper gasket. None of the new replacements have these. Is this significant? The Wagner technical line said there were no complaints of leaky wheel cylinders* and they delete ridges on easy-to-machine surfaces. Hose ends, which might distort during crimping, generally do have ridges machined in. Copper gaskets are still used on new vehicles and are, therefore, readily available in correct sizes locally.

A few years ago, new wheel cylinders were not packaged with bleeder screws or copper gaskets. Inspect new parts. Stainless steel bleeder screws are available and seem like a good idea to eliminate one corrosion problem. Dope treads liberally with an anti-seize compound before installing. This not only delays rusting, but also prevents air from entering during bleeding. Also, use an anti-seize compound to liberally coat adjuster screw threads and inside the end cap where it contacts the wheel cylinder. This has to turn relative to the wheel cylinder during shoe adjusting and will rust solid if not well protected.

Shoes and Links

We reviewed shoes in This Old Truck, September/October 1999, Vol.7 No. 4. A good shoe reliner can use oversized linings which will compensate for worn drums. This is important for good initial break performance. I recently started putting wide masking tape over the lining as I removed shoes from the box. I can later strip off greasy finger prints with the tape just before the drums go on.

|

| Masking tape protects linings from grease during link change-over and assembly. |

Huck shoes have links, pins, and friction springs, which originally came with a heavy cadmium plating which usually holds up well. It would be a step backward to sandblast off the cadmium to apply paint here. All pivoting parts need a dose of anti-sieze material as they go back together. If lock rings are pried up carefully, they can be reused many times. Make a U-shaped tool from bar stock to use with a C clamp to relieve pressure on a friction spring so a small lock ring can be removed damage free.

|

| Make a U-shaped tool from bar stock to relieve friction spring tension. |

As the shop manual says, the front facing shoe does most of the work, so if the front facing shoe is worn, but the rear facing shoe linked to it is not, they can be reversed, and new shoes may not be needed. Change shoes from left to right side of truck to minimize link swapping.

Drums

these are getting very hard to find new, and used drums are usually worn oversized. The best advice is to not turn drums unless absolutely necessary. When our trucks were in everyday use, drums were almost never turned and rarely presented problems.

If grooves are cut into drums from over-worn riveted linings, new linings will eventually seat into the grooves. If the grooves are really deep, it is time to go hunting for new drums. One of my parts trucks had a drum split along a rivet groove. This is a good argument for installing bonded linings - no rivets to gouge drums.

Many state safety inspections will unnecessarily reject a truck with drums worn more than 0.060" oversize. (See This Old Truck, March/April 1997, Vol. 5 No. 2, "Break Drums"). Larger drums can wear up to 0.090" with no ill effects, but challenging a saftey inspector would be fruitless.

Vacuum Booster

We can use all the stopping power available now, and an original vacuum booster such as a Hydrovac is a good investment for trucks larger than half-ton. These were available from 1946 on and can easily be installed or retrofitted. They reduce pedal effort by about two-thirds, which can greatly shorten stopping distances.

I don't recommend a vacuum booster with silicone brake fluid. A diaphragm leak will allow silicone to enter the combustion chamber and burn to colloidal silica, or sand, an engine abrasive.

* The manufacturer's technician had no reports of leaking wheel cylinders. The implication is the company would correct any problems showing a trend. This means users must report problems to their suppliers, and suppliers must follow up by informing the factory if we are to continue improving our parts supply. Constructive criticism must reach the people who can adjust engineering.

Bob Adler is owner of Adler's Antique

Autos, Stephentown, New York, and

specializes in GM truck restoration.

He can be reached at 518-733-5749.